With freecooling systems, the aim is to reduce energy consumption in chillers by using the cooling capacity of outside air.

CONTENTS

1 - TECHNICAL SHEET

2 - GENERAL

It is a complement that can be installed in any type of hydraulic configuration and its main objective is to reduce electricity consumption in chillers, so it is suitable when:

-

There is a sufficient number of hours with low outside temperature

-

Systems with high working temperature

-

High cost of electrical energy

-

The combination of all the factors that offers an interesting payback

The type of configuration can be in series or in parallel, and it must be taken into account that the savings potential changes significantly, so much so that the investment loses profitability.

They are usually sizable teams, so space could be a limiting factor.

The type of equipment to be used would be of the drycooler type, drycooler with an adiabatic system, cooling tower (open or closed) or even a cold source such as well or river water, although these are less common.

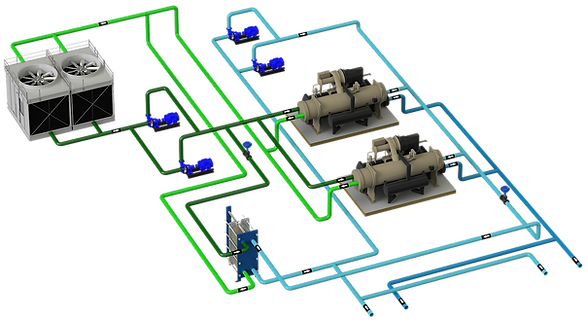

In an installation with water-cooled chillers that already have heat dissipation elements, it could be used to use them as freecooling when there is no need for mechanical cooling.

3 - TYPES OF FREECOOLING IN SERIES AND PARALLEL

The above diagram shows the 2 freecooling options:

Position A, parallel. In this configuration, the freecooling equipment is integrated into the plant as one more generator. Should consider:

-

There is only total freecooling capacity, that is, when the design outdoor temperature is reached and the setpoint temperature cannot be reached, the equipment must stop as it would not contribute anything to production.

-

When the equipment is not designed to cover the full load and it is below the outside design temperature, there will be chillers running along with the equipment and they will all be partializing at the same % load.

Position B, in series (or sidecar). The freecooling equipment is placed in the return of the serial installation, in such a way that:

-

Below the outside design temperature, it will be able to achieve the setpoint at the outlet, total freecooling. If the equipment is sufficient to meet the demand, the collector inlet temperature will be the setpoint and the chillers will not start. However, if it does not have enough capacity, the return water will be mixed with freecooling water, and the mixture will enter the chillers.

-

Between the design outdoor temperature and the system setpoint, there will be partial freecooling. The system tries to cool as much as possible, knowing that the rest will be cooled by the chillers.

4 - PARTIAL AND TOTAL FREECOOLING

When is total freecooling and partial freecooling considered?

Let's take an example of a system:

-

Cold water set point 20ºC

-

Design of the drycooler, set point 20ºC with an OAT of 15ºC

-

Capacity 1200 kW

Total Freecooling, the outdoor temperature is below the equipment design point (15ºC). With the drycooler it is enough to meet all the demand.

Partial Freecooling, the outside temperature is between 15ºC and 20ºC. The drycoler is not capable of reaching the set point of 20ºC, but it is capable of lowering the return temperature of the installation somewhat, and the rest must be cooled by the chillers.

The main advantage of partial freecooling is that the number of hours you have is usually significant and therefore the potential for energy savings is much greater.

Note: The RITE in IT 1.2.4.5.1 Free cooling by outside air, indicates that with a drycooler type configuration, it must be in series.see more

5 - TYPES OF EQUIPMENT

5.1 DRY COOLERS

A drycooler is a cooler made up of a battery that circulates water inside and air moved by fans outside.

Configurations vary by size, being flat or V-shaped.

Parameters to take into account in the selection:

- Set point temperature

- DRY outside temperature at which it is achieved. A very small temperature difference (approach) would result in a very large unit, and with a very large approach you would be losing hours of potential savings. A typical value is 5ºC, but the designer must seek the balance between investment and amortization.

Continuing with the previous example, the psychrometric diagram of the outside air that can be used for freecooling is shown:

5.2 DRYCOOLERS WITH AN ADIABATIC SYSTEM

The adiabatic system seeks to reduce the temperature of the air entering the coil and therefore obtain more hours of freecooling. Although it is true that these systems are used more for condensation and not so much for freecooling, it is an option that can be taken into account to increase operating hours. The inlet temperature will be a function of:

-

Outdoor temperature and relative humidity

-

Efficiency of the humidification system

Note: The adiabatic system logically has a water consumption that must be taken into account, both at the level of operating and maintenance costs and environmental.

Types of adiabatic cooling systems.see more

-

Spray

-

Tights

-

wetting panels

Let us see below the work area of the psychrometric chart, considering the previous values (20ºC setpoint and 5º approach) and that the system has a 100% humidification efficiency:

The blue area on the left shows total freecooling dry operation without humidification, limited to an outdoor temperature of 15ºC.

The second blue area represents the total freecooling operation with active adiabatic. The limit line of operation is the humid temperature of 15ºC (considering a humidification efficiency of 100%).

Between the wet bulb temperature between 15ºC and 20ºC there is partial freecooling.

The drier the air, the more humidifying capacity it has and the more it can cool down.

This graph represents the climatic data record, in this case for Almaraz, in the form of a monotonic curve.

The yellow dotted line represents the hourly cumulative wet temperature and all dry temperatures that have occurred with that wet bulb temperature.

The number of hours that can be worked with total freecooling exceeds 6,000 and for total + partial freecooling, almost the entire year.

6 - DESIGN RECOMMENDATIONS

Priority configuration in series over parallel, to take advantage of the possibilities of partial freecooling

Protection systems against freezing with the system stopped, glycolate the installation

In case of adiabatic system pay attention to:

-

Water spray systems:

-

water quality, hardness

-

water pressurization

-

Filtration of supply water and treatment with UV light

-

Need for battery protection

-

-

Systems with panels:

-

The thickness of the panel impacts on the efficiency of humidification and additional pressure on fans (consumption)

-

panel material

-

Panel cleaning and maintenance

-

Control of the humidification system

-