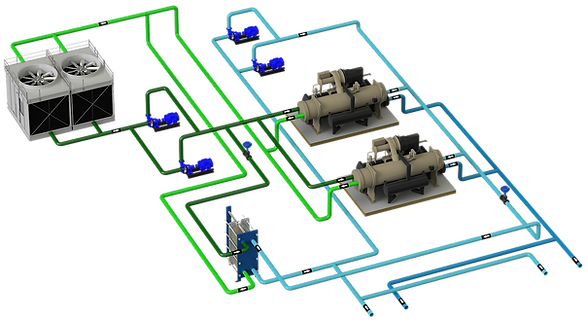

These are the systems that the same pump or group of pumps move the water through the generators and through the rest of the installation to the terminal units.

The distribution is variable flow

CONTENTS

1 - TECHNICAL SHEET

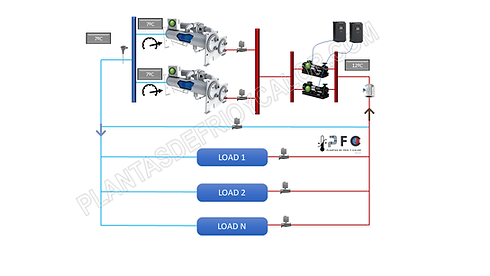

6 - BY-PASS VALVE

Another differentiating element of a VPF system and which is vital to ensure the success of the system.

Its function is to open the by-pass modulatingly to ensure that it does not operate below the minimum flow rate of the chillers.

It is a valve that can be subjected to the highest differential pressure in the system if it is located in the header.

Therefore, it must be capable of modulating throughout its operating range in all circumstances.

For what flow? A common mistake is to think that it is sized for the flow of one of the chillers.

Where it is located? Three common options:

-

Close to the discharge of chillers and suction of pumps, which presents the greatest energy savings, but requires a valve capable of operating at high pressure. With this location, if the system requires chilled water quickly and there is no circulation through the distribution circuit, there could be a delay.

-

3-way valve in some terminal units, simplifies the operation and the response time in receiving cold water, but against it there is an overconsumption and oversizing of the pumping system.

-

Locate the 2-way valve at the end of the circuit, with the advantage that the valve is subjected to less pressure and helps modulation, but there will be higher pumping costs due to subjecting the circuit to higher pressure during operation.